- Engine speed: 270 rpm

- Initial screw speed: 1000 rpm

- Drive output above 130 HP

- Weight: 1,6 tonnes

- Noise level: 73,6 dB

- Output: 3.000 – 5.000 m3/h

- Operation speed: 2-15 km/h

- Made in Austria

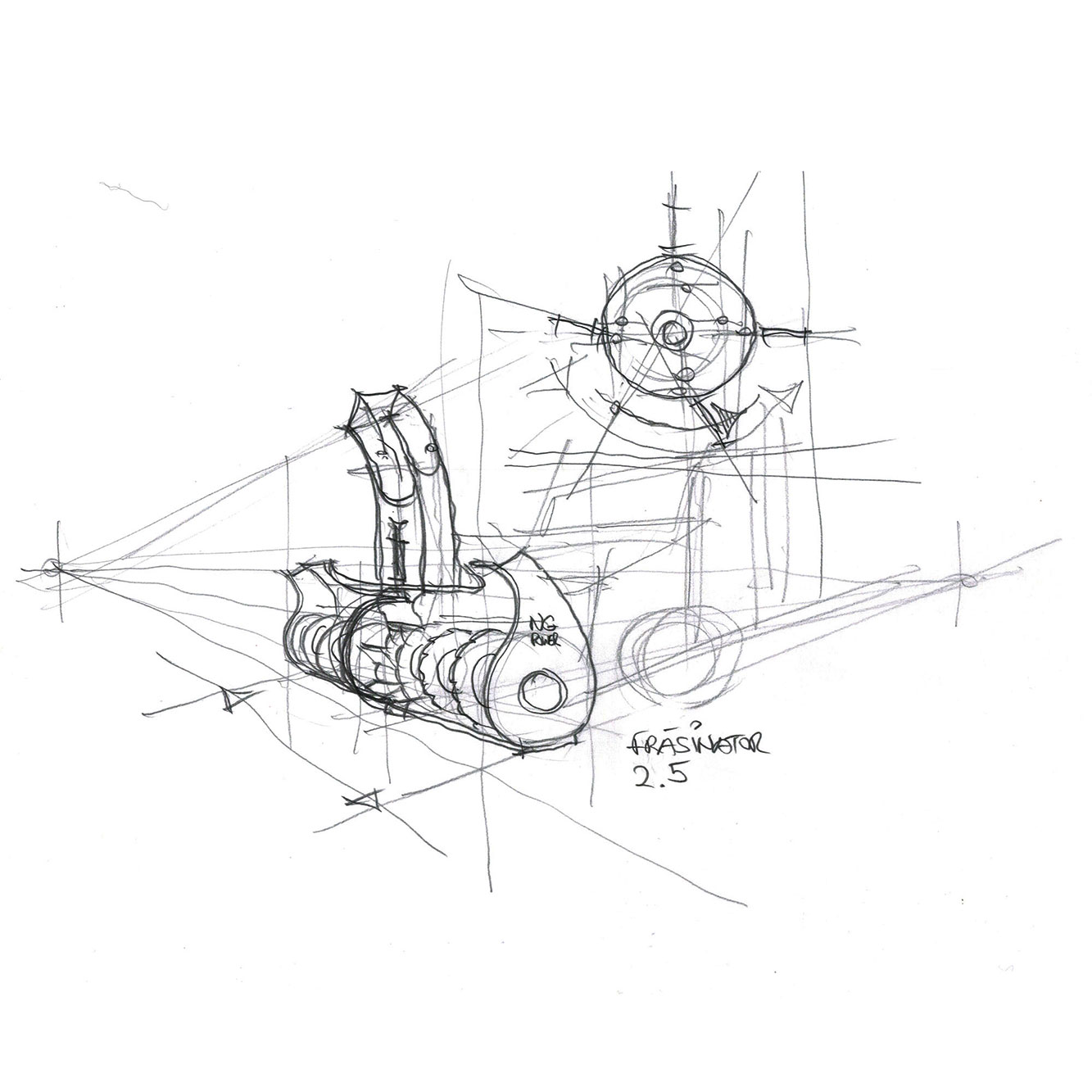

The Fräsinator ECO 3.0

- Low noise level

- NG Green Technology as standard

- Arcjet drive technology

- Mechanical and hydraulic operation

- Controlled via the controls on the carrier vehicle

- Operation-friendly friction clutch

- Dual-direction turning control

- Hydraulic level control

- Hydraulic expulsion direction settings

- Expulsion distance control through adjustable expulsion chute

- All parts are replaceable

The big difference

Standard milling machines are therefore so inefficient, since the blades press the bulk material directly into the interior walls of the impeller chute. Friction occurs as a result, causing a high expenditure of energy.

Through the use of optimum physical processes, the impeller blades accelerate their revolutions without external force effect. Unlike standard milling machines, little energy is lost.

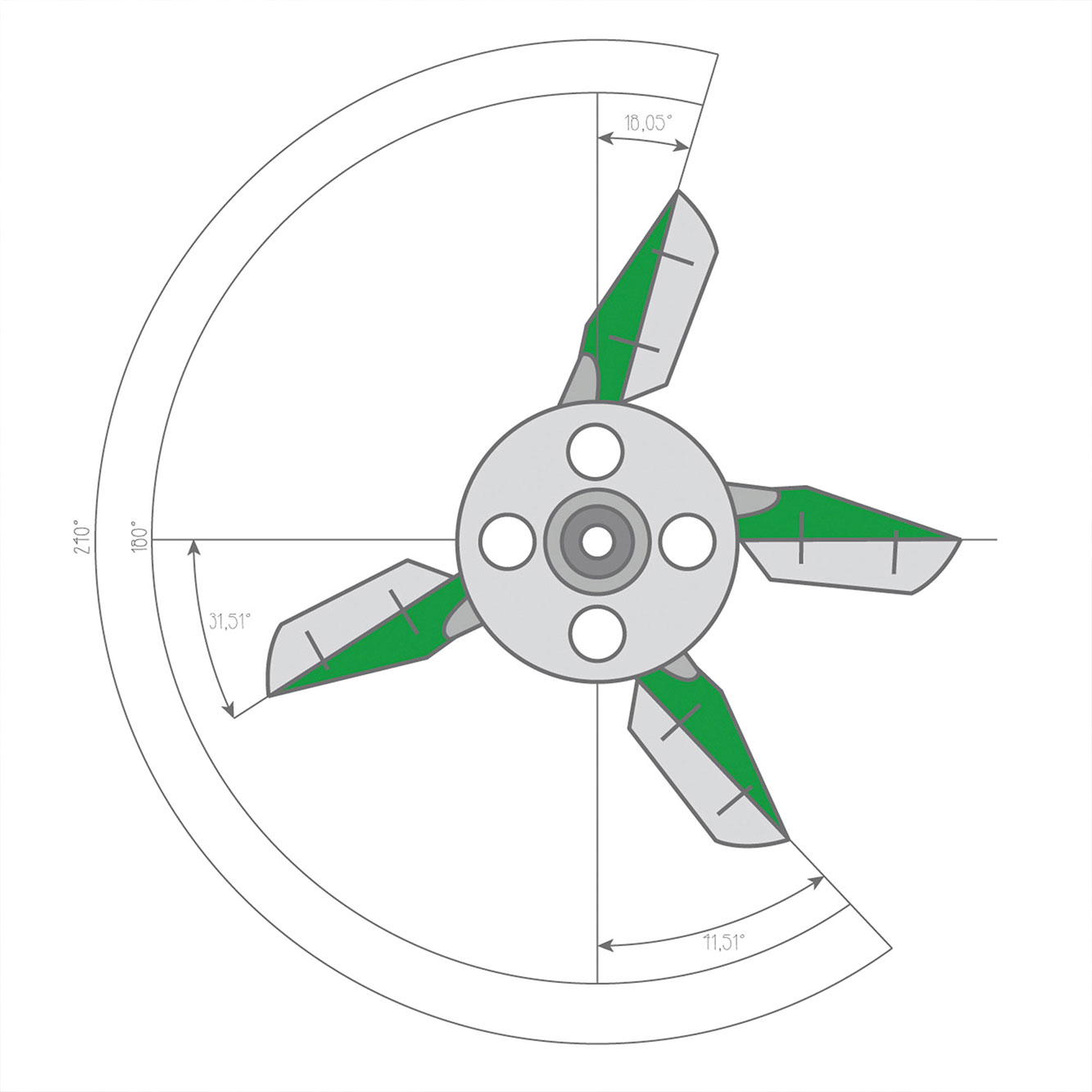

The NG Green Technology

Powerful but gentle – How can this work?

The secret lies in the build up of the world-patented acceleration wheel – the NG Green Technology.

It is a key part of our invention and can be filled from both sides, as it is on the same shaft as the auger gear.

Standard milling machines are therefore so inefficient, since the blades press the bulk material directly into the interior walls of the impeller chute. Friction occurs as a result, causing a high expenditure of energy.

Through the use of optimum physical processes, the impeller blades accelerate their revolutions without external force effect. Unlike standard milling machines, little energy is lost.

Also the noise development during operation is relatively low and the efficiency also has an effect on the size of the Fräsinator: The design is compact and can be varied according to the area of use.